In today’s industrial ecosystem, VMC Machine Job Work has become synonymous with precision, performance, and perfection. Whether it’s for creating intricate mechanical components or achieving flawless surface finishes, the role of a Vertical Machining Center (VMC) is indispensable. Shreeji Engineering Works, a trusted Manufacturer and Service Provider, has mastered the art of turning raw materials into precision-engineered components that meet exact industry standards.

Every component’s life cycle depends on the precision of its machining. A fraction of a millimeter can decide whether a part endures heavy loads or fails under pressure. That’s where the engineering edge of advanced VMC machining defines the difference between good and exceptional.

The Technical Core of VMC Machine Job Work

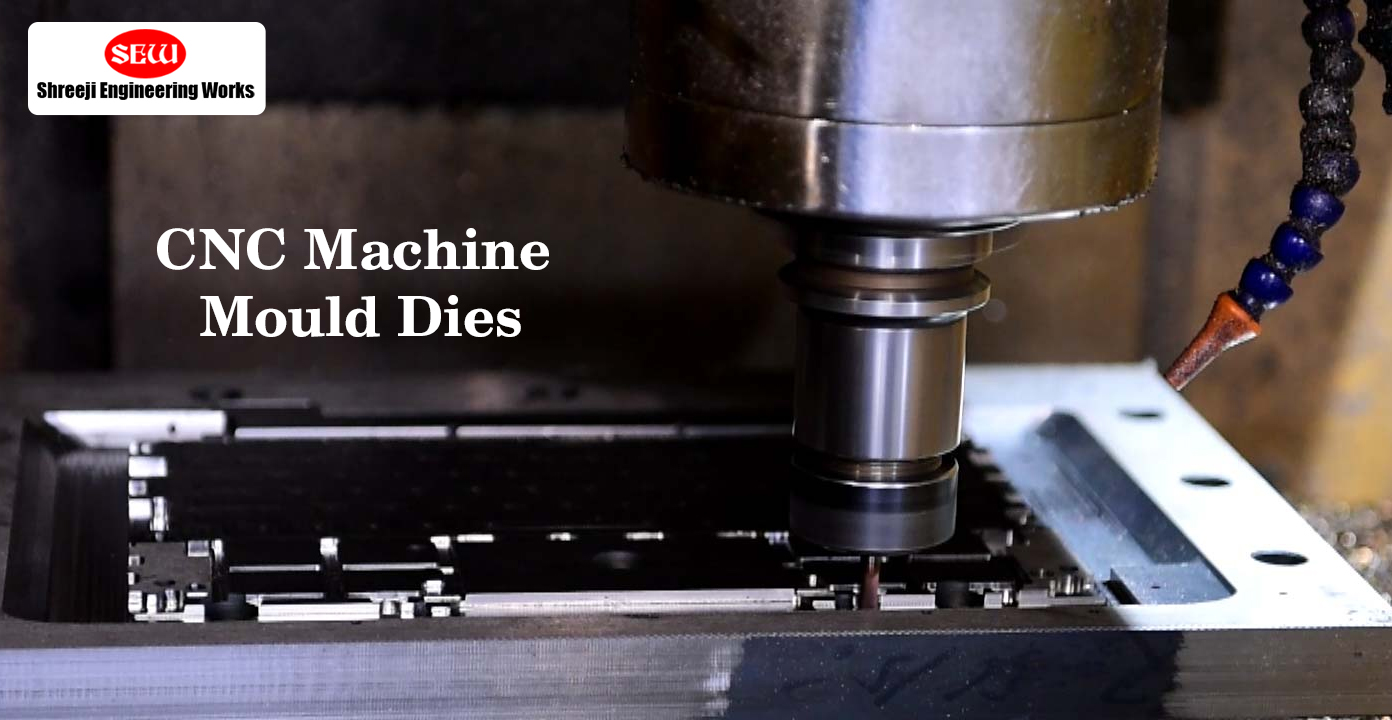

A VMC (Vertical Machining Center) operates with computer numerical control to achieve high-accuracy cutting, drilling, milling, and shaping. Unlike manual machining, which relies on operator skill, a VMC is programmed to deliver micron-level precision consistently.

Shreeji Engineering Works uses cutting-edge multi-axis VMC machines equipped with automatic tool changers and digital feedback systems. These features ensure consistent results, reduced errors, and extended component life. The integration of CNC technology, servo-controlled drives, and precision tooling contributes to achieving repeatable accuracy and superior surface finish.

The company’s VMC job work process includes:

- CAD model interpretation for dimensional consistency

- Toolpath generation through CAM software

- Automated cutting and drilling with minimal material wastage

- Final dimensional verification using coordinate measuring machines

Each of these steps is executed under strict quality protocols to ensure every machined part withstands operational stress, heat, and wear effectively.

Backed by a hardworking team, we are capable of offering the vmc machine job work as per the exact requir read more...

Owing to our capacity of meeting the exact requirements of the clients, we are supplying quality precisio read more...

Established as a dignified name, we are the celebrated organization in the market offering quality indust read more...

This is due to our rich industry experience and knowledge; we are able to offer optimum quality cnc machi read more...

Precision Machining and Its Impact on Component Longevity

The longevity of machine parts depends not only on the material used but also on how precisely they are machined. When the cutting tool geometry, feed rate, and spindle speed are optimized, it minimizes surface roughness, reducing friction and wear during operation.

For example, when machining stainless steel shafts or aluminum housings, improper cutting parameters can create micro-tears or uneven finishes. However, VMC machine job work eliminates such irregularities through controlled machining speeds and lubrication, resulting in longer-lasting parts.

Shreeji Engineering Works employs a combination of:

- High-speed spindle technology for dimensional accuracy,

- Coolant-fed tooling systems for temperature control,

- Vibration-dampening structures that ensure stability, and

- Real-time performance monitoring for process reliability.

Each of these parameters contributes to extending the operational lifespan of every machined part.

Material Adaptability and Technical Flexibility

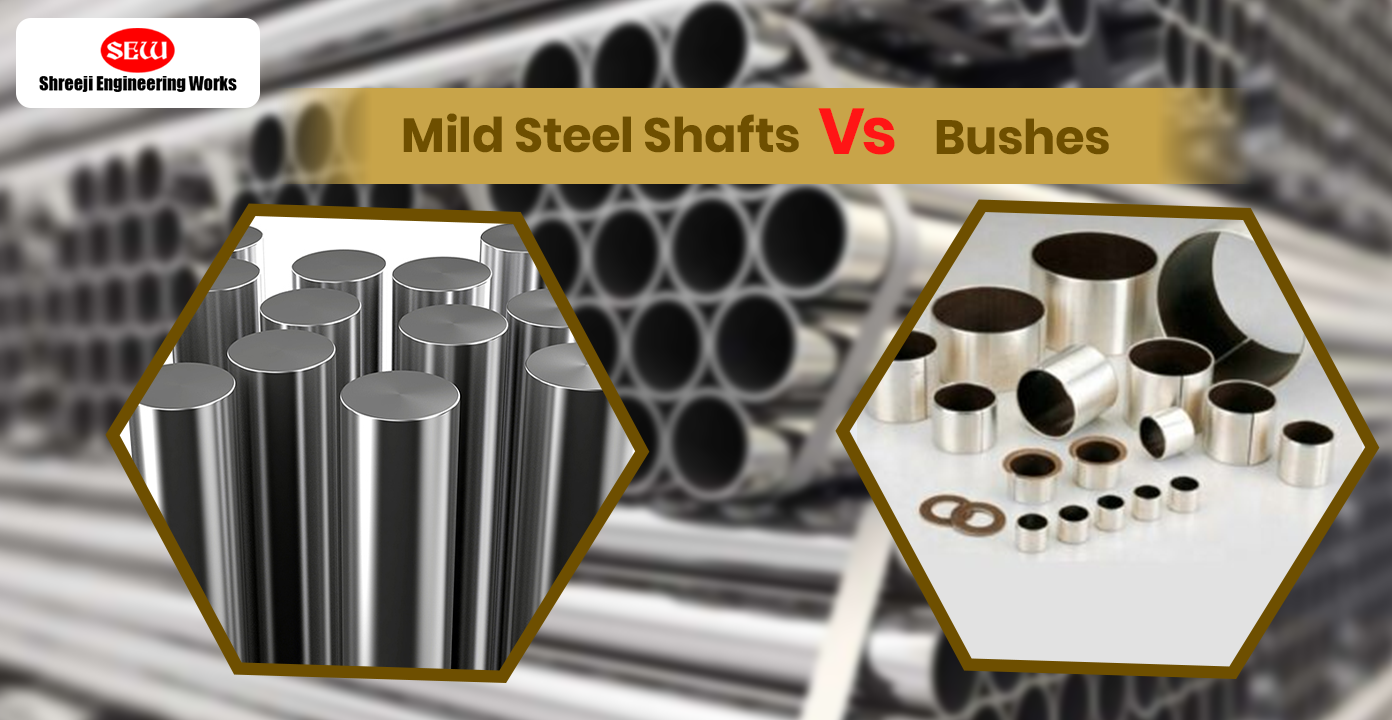

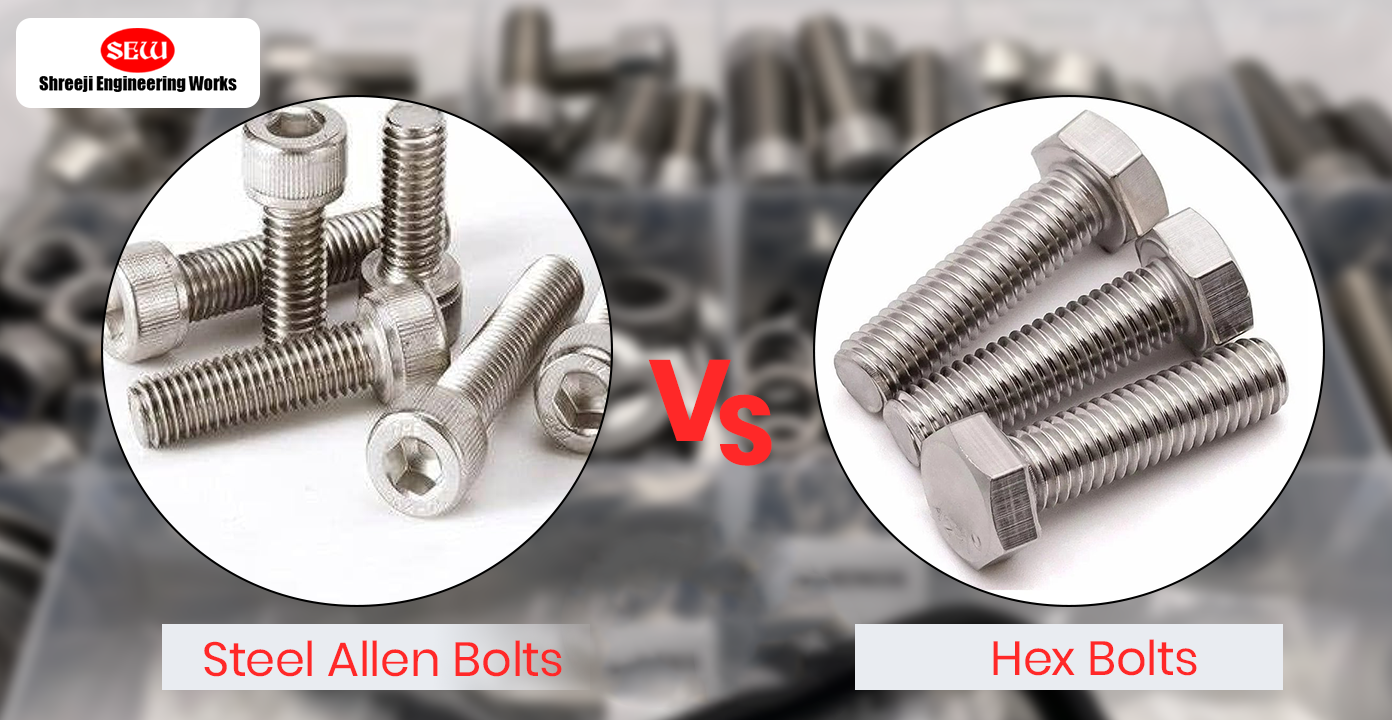

One of the biggest advantages of VMC machine job work is its adaptability to different materials. Whether working with mild steel, stainless steel, aluminum, brass, or cast iron, the machine adjusts spindle RPM, tool feed, and cutting depth automatically.

This adaptive machining capability allows Shreeji Engineering Works to cater to diverse industries — from automotive to heavy machinery. Components that undergo high mechanical stress, such as housings, fixtures, molds, and brackets, are machined with utmost precision to maintain dimensional tolerance and mechanical integrity over prolonged use.

Through tool simulation and predictive analysis, the company ensures that material hardness and machining sequence are optimized, reducing tool wear and ensuring longer machine part life.

Advanced Process Controls and Digital Precision

In the modern era of manufacturing, digital precision control has redefined VMC job work. Using CNC-driven automation and sensor feedback systems, the company maintains a consistent machining accuracy of up to ±0.005 mm.

Shreeji Engineering Works utilizes integrated machining software that:

- Analyzes cutting loads in real time,

- Adjusts feed rates to prevent tool wear, and

- Predicts part deformation during machining.

This integration of Industry 4.0 principles ensures that every machined part aligns with the highest standards of durability and repeatability — enhancing both part longevity and machine reliability.

Surface Finish and Dimensional Stability

A fine surface finish is more than aesthetics; it’s a critical factor that determines how long a part lasts in operation. A smooth finish reduces friction, prevents corrosion, and enhances assembly compatibility.

Through advanced toolpath optimization and multi-pass finishing, Shreeji Engineering Works ensures consistent surface quality. Using precision cutters and high-grade lubricants, each job achieves a surface roughness as low as Ra 0.8 µm, significantly increasing part endurance.

Additionally, the team focuses on maintaining dimensional stability through temperature-compensated machining — ensuring each part retains its structural accuracy even after thermal expansion or contraction.

Custom Engineering Solutions for Industrial Applications

What sets Shreeji Engineering Works apart is its ability to offer customized VMC machine job work solutions for specialized applications. Each client’s requirement is treated uniquely, from prototype development to bulk production.

Industries that rely heavily on this service include:

- Automotive manufacturing (engine brackets, transmission housings)

- Textile machinery (spindles, guides, rollers)

- Tooling and fixture industries

- Heavy engineering and fabrication units

These components, once precisely machined, exhibit superior wear resistance, load-bearing strength, and fatigue performance, translating directly to enhanced lifespan and reduced downtime.

Quality Assurance and Inspection Protocols

At Shreeji Engineering Works, quality control is not an afterthought — it’s embedded in every phase of production. The company employs multi-stage inspection systems, including:

- Coordinate Measuring Machines (CMM)

- Laser alignment tools

- Surface roughness testers

- Optical comparators

Each machined component undergoes dimensional verification, hardness testing, and surface evaluation to confirm adherence to industry specifications. This commitment ensures long-lasting performance and trust in every part manufactured.

Future of VMC Job Work – Towards Smart Manufacturing

As technology evolves, the future of VMC machining lies in integration with AI, IoT, and smart sensors. These systems will enable self-learning machining parameters, predictive maintenance, and adaptive performance control.

Shreeji Engineering Works continues to invest in next-generation equipment to remain at the forefront of precision engineering. By combining experience with innovation, the company is paving the way for intelligent, data-driven machining processes that ensure components last longer, perform better, and meet global standards.

About Shreeji Engineering Works

Shreeji Engineering Works is a leading Manufacturer and Service Provider specializing in VMC Machine Job Work and precision-engineered industrial components. With years of expertise in machining, tooling, and fabrication, the company delivers consistent quality across every project. Its commitment to innovation, precision, and customer satisfaction has made it a trusted partner across industries.

Frequently Asked Questions

1. What is VMC Machine Job Work, and how does it differ from traditional machining?

VMC Machine Job Work involves the use of Vertical Machining Centers (VMCs) operated by computer numerical control (CNC). Unlike traditional manual machining, VMC ensures higher precision, repeatability, and dimensional accuracy.

2. How does VMC machining improve the longevity of machine parts?

The precision and surface finish achieved through VMC machining reduce internal stress, friction, and heat generation in components.

3. Which materials can be processed under VMC Machine Job Work?

Mild steel, stainless steel, aluminum, copper, brass, and cast iron.

4. What industries benefit most from VMC Machine Job Work?

Industries such as automotive, textile machinery, heavy engineering, tooling, and fabrication rely heavily on VMC machining. The process is ideal for creating precision components like shafts, housings, brackets, and molds that demand high structural reliability.

5. What makes Shreeji Engineering Works stand out in precision VMC machining services?

Every part undergoes detailed CAD-CAM processing, inspection, and dimensional verification to ensure the highest standards of quality and performance.