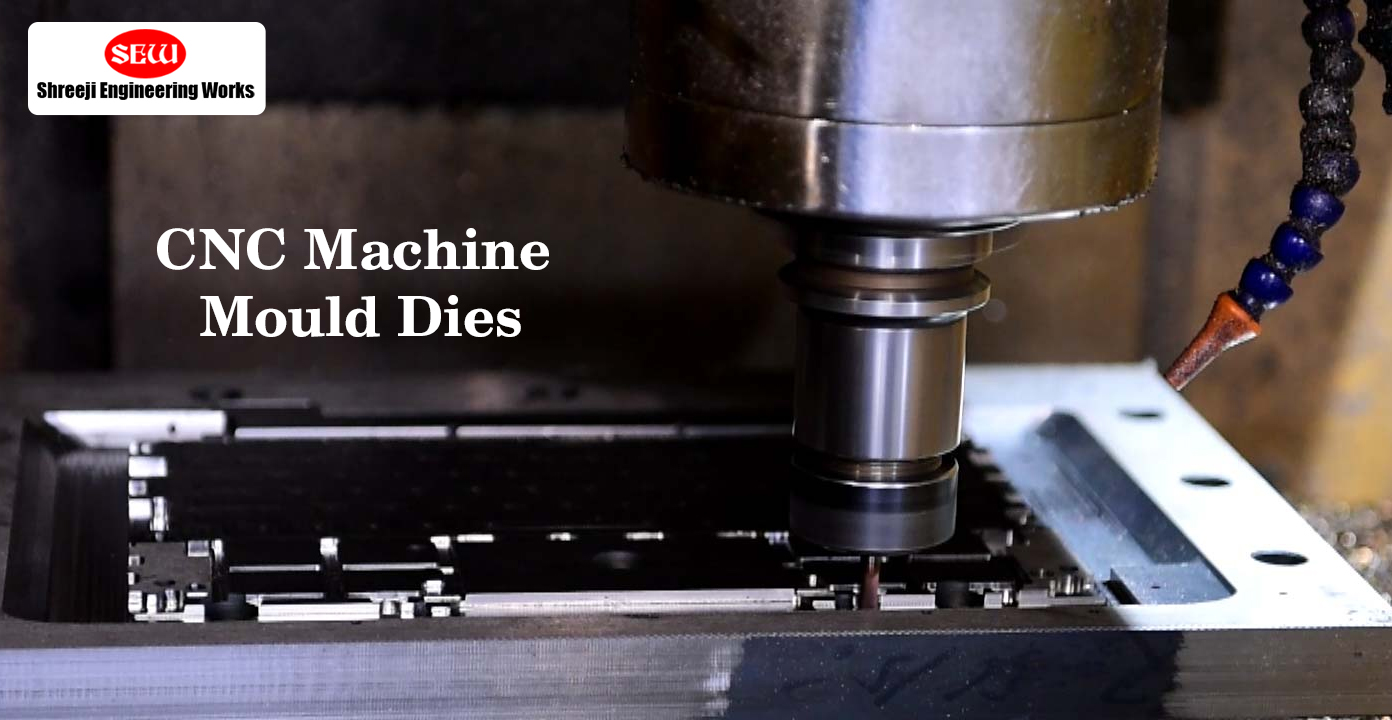

In the fast-paced industrial manufacturing sector, precision and efficiency are critical. One of the essential tools ensuring accuracy in metal fabrication is the Metal Cutting Die. Manufactured with high-grade materials and engineered for durability, Shreeji Engineering Works stands as a trusted manufacturer and supplier of top-tier Metal Cutting Dies that meet global industrial standards.

Metal cutting dies are indispensable in industries ranging from automotive to aerospace, electronics, and construction. They are designed to handle rigorous operations such as stamping, shearing, blanking, and forming metal sheets. The efficiency and quality of a cutting die directly impact production consistency, material utilization, and operational safety.

Key Features of Metal Cutting Dies:

The excellence of Shreeji Engineering Works’ metal cutting dies lies in their meticulously designed features:

- High-Grade Steel Construction: Manufactured using hardened steel, ensuring long-term wear resistance and consistent cutting precision.

- Precision Engineering: CNC-machined to exact tolerances, minimizing errors in metal fabrication.

- Multi-Layer Die Configuration: Allows for versatile operations, including blanking, piercing, and bending in a single tool.

- Heat Treatment: Optimized hardness levels prevent deformation during high-pressure cutting operations.

- Custom Designs: Tailored dies to match specific production requirements and metal thicknesses.

- Corrosion Resistance: Surface treatments to extend lifespan even under harsh factory environments.

Technical Specifications

Understanding the specifications of metal cutting dies is essential for selecting the right tool for your operation:

- Die Material: High-carbon alloy steel or tool steel (D2, A2 grades)

- Cutting Edge Hardness: 58–62 HRC

- Base Plate Thickness: 15 mm – 100 mm, depending on die type

- Operational Temperature Range: Up to 200°C for continuous operation

- Compatible Metal Thickness: 0.5 mm – 10 mm

- Tolerance Accuracy: ±0.01 mm

- Surface Finish: Ra 0.4 – 0.8 μm

- Die Life Cycle: 500,000 – 2,000,000 cuts, depending on material and usage

- Customization: Available upon request for specific industrial applications

Types of Metal Cutting Dies

Metal cutting dies can be categorized according to their functional application:

- Blanking Dies: Designed to cut sheet metal into desired shapes.

- Piercing Dies: Punch holes in metal sheets with precision.

- Progressive Dies: Multiple operations in a single stroke, ideal for mass production.

- Compound Dies: Combine blanking and piercing in one operation.

- Forming Dies: Shape metal sheets into bends or curves without removing material.

Shreeji Engineering Works provides all these types with customization options based on client requirements, ensuring that each die perfectly matches the metal sheet thickness, hardness, and production speed.

Advantages of Using Shreeji Engineering Works’ Metal Cutting Dies

- Enhanced Production Efficiency: High precision reduces errors, scrap, and rework.

- Durability and Longevity: Advanced materials and heat treatment extend die life.

- Consistent Quality: Uniform results across thousands of operations.

- Reduced Maintenance: Engineered for wear resistance, requiring minimal downtime.

- Versatility: Compatible with a range of sheet metals, including stainless steel, aluminum, copper, and brass.

- Cost-Effectiveness: Optimized designs reduce material waste and operational costs.

Applications Across Industries

The industrial relevance of metal cutting dies is extensive:

- Automotive Industry: Manufacturing body panels, chassis components, brackets, and engine parts.

- Aerospace Sector: Precision components for aircraft, drones, and satellite parts.

- Electrical and Electronics: Cutting enclosures, panels, and connectors with tight tolerances.

- Construction Industry: Fabricating metal parts for frameworks, roofing, and machinery.

- Consumer Appliances: Producing casings, housings, and internal components for household devices.

Each industry requires precise cutting to ensure safety, reliability, and functionality. Shreeji Engineering Works’ dies cater to these exacting standards, ensuring high-performance results.

Maintenance Guidelines for Metal Cutting Dies

Proper maintenance ensures the longevity and efficiency of cutting dies. Here are some best practices:

- Regular Cleaning: Remove metal debris and lubricants after each operation.

- Lubrication: Apply suitable lubricants to minimize friction and wear.

- Inspection: Regularly check for cracks, chipping, or misalignment.

- Sharpening: Maintain cutting edges at the recommended hardness to prevent deformation.

- Storage: Store in a dry, temperature-controlled environment to prevent rust and corrosion.

- Calibration: Periodically verify alignment with CNC machines or press equipment to maintain cutting accuracy.

Customization Options

Shreeji Engineering Works offers extensive customization for cutting dies, including:

- Die shapes for irregular or complex metal parts

- Multiple cutting layers for sequential operations

- Specific material grade selection to handle different metals

- Heat treatment variations for optimized hardness

- Integration with progressive or compound die setups

Customization ensures that each die meets client-specific production requirements, enhancing operational efficiency and quality.

Why Choose Shreeji Engineering Works?

Shreeji Engineering Works is not just a manufacturer but a trusted partner for industries requiring precision metal cutting tools. The company emphasizes:

- Advanced Engineering Expertise: Skilled designers and technicians using CAD/CAM and CNC technology.

- Quality Assurance: Stringent inspections and testing procedures to ensure top-notch performance.

- Timely Delivery: Efficient manufacturing processes ensure that clients receive their dies without delay.

- After-Sales Support: Guidance on maintenance, usage, and troubleshooting to maximize die life.

FAQ (Frequently Asked Questions)

Q1: What metals are compatible with Shreeji Engineering Works’ cutting dies?

A1: Our dies are compatible with stainless steel, mild steel, aluminum, copper, brass, and other industrial-grade metals.

Q2: How long do the cutting dies last?

A2: Depending on usage and material, the dies can last between 500,000 to 2,000,000 cuts with proper maintenance.

Q3: Can custom die shapes be designed?

A3: Yes, we offer fully customized dies to suit specific shapes, metal thickness, and production requirements.

Q4: How are the cutting edges treated for durability?

A4: Cutting edges undergo precision heat treatment to achieve hardness levels between 58-62 HRC for long-term wear resistance.

Q5: Is lubrication required for the dies?

A5: Yes, using appropriate lubricants reduces friction and ensures optimal cutting performance.

Q6: Can these dies be used in automated production lines?

A6: Absolutely, our dies are designed for both manual press operations and fully automated CNC lines.

Q7: How often should maintenance be performed?

A7: Basic cleaning and inspection should be performed daily, while sharpening and calibration can be done monthly or as per usage intensity.