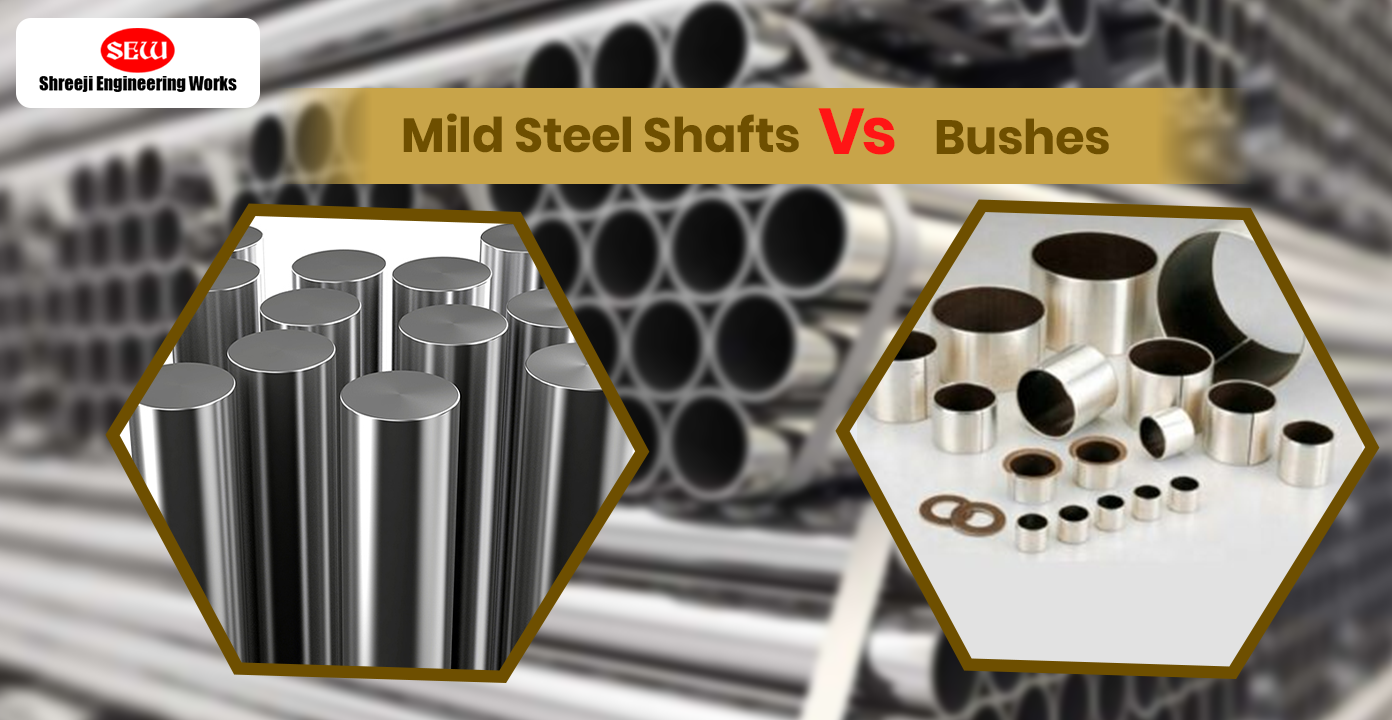

In any mechanical system, even the most advanced machines rely on basic components to function smoothly and reliably. Among these, shafts and bushes play a critical role in power transmission, movement control, and load handling. Their performance directly impacts machine efficiency, durability, and safety.

Choosing the right material for these components is equally important. The material must offer strength, machinability, and wear resistance while remaining cost-effective. Mild steel has emerged as one of the most commonly used materials for such applications due to its balanced mechanical properties and wide industrial acceptance.

With years of experience in manufacturing precision-engineered components, Shreeji Engineering Works specializes in supplying high-quality mild steel shafts and bushes that meet industrial performance standards and application requirements.

What Are Mild Steel Shafts?

Mild steel shafts are solid mechanical components designed to transmit rotational motion, torque, or power between different machine parts. They act as the central axis for rotating elements such as gears, pulleys, bearings, sprockets, and couplings, making them essential to the smooth functioning of mechanical systems.

They are produced in various diameters, lengths, and profiles, including round, stepped, keyed, and splined designs, depending on load requirements and operating conditions.

Mild steel shafts are widely used in industrial machinery, motors, conveyors, pumps, agricultural equipment, and general engineering applications where moderate load capacity, reliability, and cost efficiency are required.

Key features and benefits of mild steel shafts include:

- Good tensile strength suitable for power transmission

- Excellent machinability for precision manufacturing

- Reliable performance under continuous operation

- Compatibility with bearings, bushes, and couplings

- Cost-effective solution for a wide range of industrial uses

What Are Mild Steel Bushes?

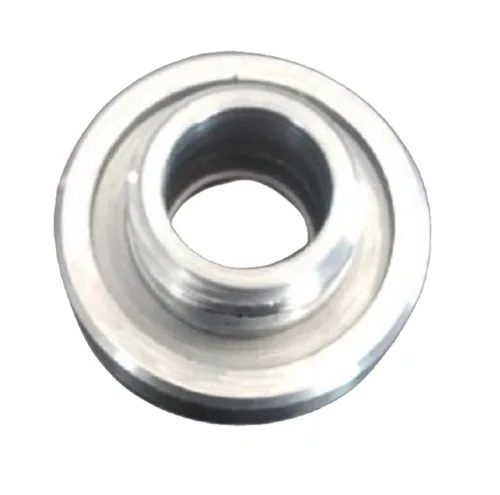

Mild steel bushes are hollow cylindrical components used as liners or sleeves between moving machine parts. Their primary function is to reduce friction, support smooth movement, and protect shafts or housings from direct wear during operation.

These bushes are manufactured from mild steel for its structural strength and ability to withstand surface pressure. They are available in different designs such as plain bushes, flanged bushes, split bushes, and custom-machined bushes, depending on application needs.

Mild steel bushes are commonly used in machinery where controlled motion and load distribution are required, such as shaft housings, pivots, hinges, gear assemblies, and heavy-duty industrial equipment.

Key features and benefits of mild steel bushes include:

- Effective reduction of friction between moving parts

- Good load-bearing and surface pressure handling capability

- Protects shafts and housings from excessive wear

- Easy to replace during maintenance cycles

- Economical and maintenance-friendly component choice

Key Differences Between Mild Steel Shafts and Bushes

| Aspect | Mild Steel Shafts | Mild Steel Bushes |

|---|---|---|

| Primary function | Act as an active mechanical component that transmits power, torque, or rotational motion between machine elements. | Serve as a supporting and protective component that reduces friction and guides smooth movement of shafts or pins. |

| Role in machinery | Directly involved in machine operation and motion transfer, making them critical to overall system performance. | Indirectly support machine operation by protecting mating parts and ensuring controlled movement. |

| Design & structure | Generally solid and precision-machined, often cylindrical, stepped, keyed, or splined depending on load and torque requirements. | Hollow, sleeve-like components designed to house shafts, pins, or rotating elements within a fixed housing. |

| Load handling | Designed to handle dynamic loads, torsional stress, bending forces, and rotational pressure during operation. | Primarily handle radial loads and surface pressure caused by friction and contact with moving components. |

| Movement behavior | Continuously rotates or transfers motion during machine operation. | Remains stationary while allowing relative movement of the shaft or pin inside it. |

| Wear characteristics | Subject to mechanical stress, fatigue, and surface wear due to rotation and load transmission. | Designed to absorb wear intentionally, protecting more expensive components like shafts or housings. |

| Friction management | Not intended to reduce friction directly; relies on bearings or bushes for smooth operation. | Specifically designed to reduce friction and support lubrication for smoother motion. |

| Maintenance impact | Replacement can be costly and time-consuming due to its critical role in machinery. | Easier and more economical to replace, making maintenance more cost-effective. |

| Precision requirement | Requires high dimensional accuracy to ensure proper alignment and vibration-free operation. | Requires precise inner diameter tolerances to maintain clearance and prevent excessive friction. |

| Typical replacement cycle | Longer service life, replaced mainly due to fatigue, bending, or major wear. | Shorter service life, replaced periodically as part of routine maintenance. |

Applications

Mild Steel Shafts:

- Power transmission systems: Mild steel shafts are extensively used to transmit torque and rotational motion between gears, pulleys, sprockets, and couplings, ensuring smooth and reliable power flow in industrial systems.

- Motors and pumps: In electric motors and pumps, mild steel shafts support continuous rotation under load, maintaining alignment and stability for efficient performance and long operational life.

- Industrial machinery: These shafts are widely applied in conveyors, compressors, agricultural machines, and manufacturing equipment where consistent rotation and mechanical strength are essential.

- Automotive and engineering equipment: Mild steel shafts are used in driveline components, gearboxes, and mechanical assemblies, offering durability and cost efficiency for automotive and general engineering applications.

Mild Steel Bushes:

- Bearings and rotating parts: Mild steel bushes act as liners within bearing housings, guiding rotating shafts or pins while supporting smooth and controlled movement.

- Reducing friction and wear: By providing a sacrificial wear surface, mild steel bushes reduce direct metal-to-metal contact, minimizing friction and extending component life.

- Machinery alignment support: Bushes help maintain proper alignment of shafts and moving parts, reducing vibration, noise, and uneven wear during machine operation.

- Heavy-duty and light-duty uses: Depending on design and thickness, mild steel bushes are suitable for heavy industrial machinery as well as light mechanical assemblies and equipment.

Benefits

Mild Steel Shafts:

- High strength and durability: Mild steel shafts offer sufficient tensile strength and resistance to mechanical stress, making them reliable for continuous power transmission applications.

- Good machinability: The material allows easy turning, drilling, milling, and threading, enabling precise customization and efficient manufacturing.

- Cost-effective solution: Compared to alloy or stainless steel options, mild steel shafts provide excellent performance at a lower material and production cost.

- Long service life: When properly designed, installed, and maintained, mild steel shafts deliver consistent performance over extended operational periods.

Mild Steel Bushes:

- Smooth operation and reduced friction: Mild steel bushes facilitate controlled movement of shafts and pins, reducing friction-related heat and operational resistance.

- Easy replacement and maintenance: Bushes are designed as replaceable wear components, allowing quick maintenance without replacing expensive shafts or housings.

- Protection for shafts and housings: By absorbing wear, bushes protect critical machine components from damage and premature failure.

- Economical for industrial use: Mild steel bushes provide a practical and budget-friendly solution for managing wear and alignment in industrial machinery.

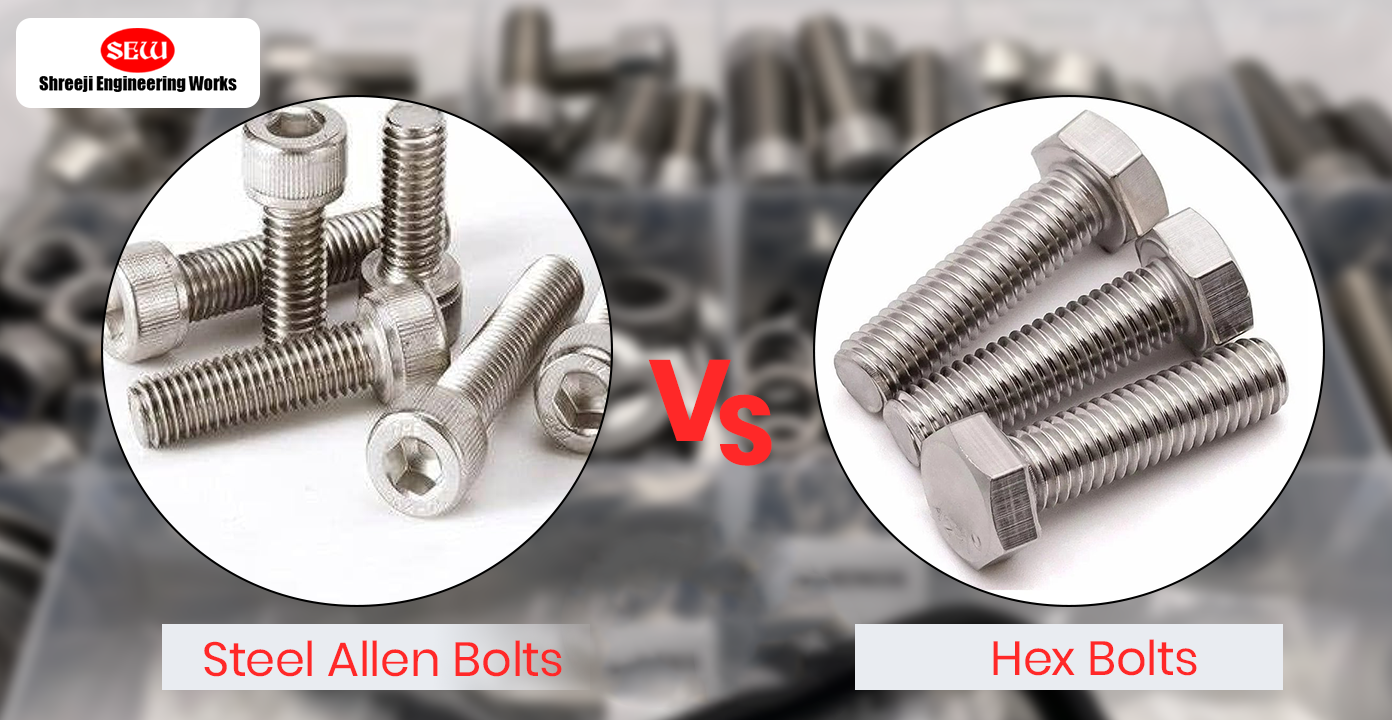

How to Choose Between Shafts and Bushes

Based on application requirement:

- Shafts should be selected when the application involves transmitting power, torque, or rotational motion between machine components.

- Bushes are required when the purpose is to support movement, reduce friction, or protect mating parts from wear.

Load and speed considerations:

- High rotational loads and continuous motion demand properly sized mild steel shafts with adequate strength,

- while bushes should be chosen based on surface pressure, operating speed, and compatibility with lubrication to ensure smooth performance.

Maintenance and replacement needs:

- Bushes are ideal in applications where regular wear is expected, as they are designed for easy replacement and lower maintenance cost,

- while shafts are long-term components that require durability and dimensional stability.

Professional guidance helps determine the correct component type, size, and tolerance, ensuring optimal performance and long service life for specific industrial applications.

Why Choose Shreeji Engineering Works for Mild Steel Components

Shreeji Engineering Works is known for delivering high-quality mild steel components manufactured with precision and consistency. Each shaft and bush is produced using accurate machining processes to ensure proper tolerances, smooth surface finishes, and dependable performance across applications. The company uses quality-tested mild steel materials that offer reliable strength and durability, making the components suitable for demanding industrial environments.

In addition to standard products, Shreeji Engineering Works also provides custom manufacturing based on client drawings or specifications, along with efficient bulk supply capabilities to meet both small and large industrial requirements. With a strong focus on quality, reliability, and technical expertise, the company has established itself as a trusted supplier of mild steel shafts and bushes for a wide range of engineering and industrial needs.