Bolts play a critical role in industrial, engineering, and construction applications, acting as essential components that hold structures, machines, and equipment together. The reliability and performance of an assembly often depend on selecting the right type of bolt for the job.

Understanding different bolt types is important because each design offers specific strength, load-bearing capacity, and installation advantages. Using the wrong bolt can lead to loosening, structural failure, or increased maintenance costs, especially in demanding industrial environments.

Stainless steel fasteners are widely used across industries due to their excellent corrosion resistance, strength, and long service life. They perform well in harsh conditions, including exposure to moisture, chemicals, and varying temperatures.

With extensive experience in manufacturing and supplying fasteners, Shreeji Engineering Works specializes in delivering reliable stainless steel bolt solutions that meet industrial standards and application-specific requirements.

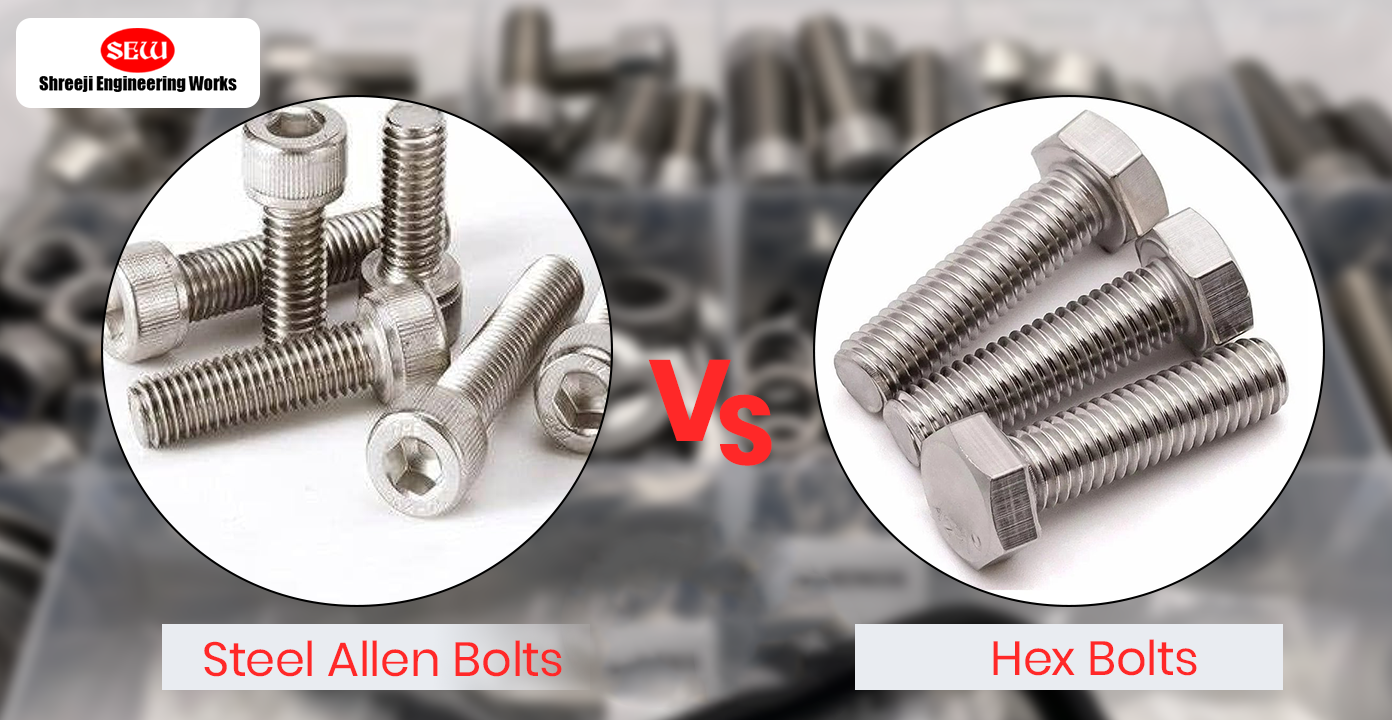

What Are Stainless Steel Allen Bolts?

Stainless steel Allen bolts, also known as socket head cap screws, feature an internal hexagonal drive that is tightened using an Allen key. This design allows the bolt head to sit flush or recessed within the surface, providing a clean and compact finish.

These bolts are commonly manufactured using stainless steel grades such as SS 304, SS 316, and SS 202, depending on the required strength and corrosion resistance. Higher grades like SS 316 are preferred in environments exposed to moisture, chemicals, or marine conditions.

Allen bolts are widely used in machinery, automotive components, equipment assembly, tooling, and precision engineering applications, where space is limited and high torque is required.

Key features and benefits of stainless steel Allen bolts include:

- High torque capability due to the internal hex drive

- Compact head design suitable for tight spaces

- Strong clamping force and secure fastening

- Excellent resistance to rust and corrosion

- Clean, professional appearance in finished assemblies

Prominent amidst the leading supplier; count on us to avail the finest stainless steel npt bolt. owing to read more...

What Are Stainless Steel Hex Bolts?

Stainless steel hex bolts are one of the most commonly used fasteners, recognized by their external hexagonal head, which can be tightened using standard spanners or wrenches. This traditional design makes them easy to install and remove, even in heavy-duty applications.

These bolts are typically produced using stainless steel grades such as SS 304, SS 316, and SS 202, offering a balance of strength, durability, and corrosion resistance. SS hex bolts are especially popular in outdoor and industrial environments where exposure to weather or chemicals is a concern.

Stainless steel hex bolts are extensively used in construction projects, structural assemblies, industrial machinery, pipelines, and heavy equipment, where strong load-bearing capability is required.

Key features and benefits of stainless steel hex bolts include:

- High strength suitable for heavy-duty applications

- Easy installation with commonly available tools

- Excellent corrosion resistance for long-term use

- Versatile usage across multiple industries

- Reliable performance under high load and stress

One stop destination for the best in class and exceptional assortment of stainless steel allen bolt; we a read more...

Key Differences Between Allen Bolts and Hex Bolts

| Comparison Aspect | Stainless Steel Allen Bolts | Stainless Steel Hex Bolts |

|---|---|---|

| Head Design & Tool Requirement | Internal hex (Allen) drive that requires an Allen key; allows the bolt head to sit flush or recessed for a clean finish. | External hexagonal head tightened using spanners or wrenches; easy to grip and widely compatible with standard tools. |

| Space Requirement for Installation | Ideal for tight or confined spaces since tightening is done from the top with minimal clearance needed. | Requires side clearance for tool movement, making it more suitable for open and accessible installations. |

| Torque Application & Grip | Offers precise torque control and a secure grip, suitable for controlled and precision assemblies. | Handles higher torque levels effectively due to larger head size and better leverage from heavy-duty tools. |

| Appearance & Finish | Clean, modern, and professional look, often preferred in visible or precision equipment. | Rugged and industrial appearance, commonly used in structural and heavy-duty environments. |

| Load-Bearing Capability | Strong enough for moderate to high loads, especially in machinery and equipment requiring accuracy. | Higher load-bearing capacity, making it suitable for structural and heavy mechanical applications. |

| Performance in High-Stress Applications | Best for precision-driven setups where controlled force matters more than extreme load. | Preferred for high-stress environments such as construction, infrastructure, and heavy machinery. |

| Durability & Long-Term Performance | Excellent durability when made from SS 304 or SS 316; performs well in controlled indoor environments. | Highly durable in long-term use, especially in outdoor or harsh industrial conditions. |

| Performance in Vibration-Prone Areas | Provides secure fastening in machinery with vibration, reducing the chance of loosening. | May require washers or locking systems to prevent loosening under continuous vibration. |

| Ease of Installation | Easy to install in compact assemblies but requires proper tool alignment to avoid socket damage. | Straightforward installation in open areas with easy access to tools. |

| Maintenance & Removal | Removal can be difficult if the internal socket is worn or clogged with debris. | Easier to remove even after long use; head damage is less common during maintenance. |

| Risk of Tool Slippage or Damage | Risk of internal socket rounding if incorrect Allen keys or excessive torque are used. | Lower risk of head damage, though worn tools can cause spanner slippage. |

Affordable price and high quality are the major attributes owing to which our mild steel foundation bolt read more...

Application-Based Comparison

The choice between Allen bolts and hex bolts often depends on the specific industry and working conditions.

- Machinery and Precision Equipment: Allen bolts are preferred due to their compact head design, precise torque control, and clean finish.

- Automotive and Engineering Industries: Both bolt types are used, Allen bolts for engine components and precision parts, hex bolts for chassis and structural elements.

- Construction and Structural Use: Hex bolts dominate these applications because of their high load-bearing strength and easy installation using standard tools.

- Precision vs Heavy-Duty Use Cases: Allen bolts are best for precision and controlled assemblies, while hex bolts are ideal for heavy-duty and load-intensive tasks.

- Indoor vs Outdoor Applications: Allen bolts are commonly used indoors in machinery and equipment, whereas hex bolts are more suitable for outdoor installations, especially when made from corrosion-resistant stainless steel grades.

Recognized amongst the famed names in the market, we are capable of delivering quality mild steel bolt to read more...

Cost & Availability Comparison

When comparing stainless steel Allen bolts and Hex bolts, cost and availability vary based on design, usage, and production scale.

Price difference:

- Hex bolts are generally more cost-effective because of their simple head design and large-scale manufacturing.

- Allen bolts tend to be slightly higher in price due to precision machining of the internal hex drive, which adds manufacturing complexity.

Availability in standard sizes:

-

Both Allen and Hex bolts are widely available in standard diameters, lengths, and stainless steel grades such as SS 304 and SS 316, making them easy to source for most industrial applications.

Bulk buying considerations:

- For bulk or repeat orders, pricing becomes more competitive for both bolt types. Hex bolts often offer better economies of scale.

- Allen bolts provide value where design precision and compact installation are required.

Overall value for money:

- The true value depends on application suitability. Choosing the correct bolt based on performance needs, rather than upfront cost alone, results in better durability, safety, and long-term efficiency.

An emerging name in the market, our organization is involved in offering mild steel hexa nut within the m read more...

How to Choose the Right Bolt for Your Application

Selecting the right stainless steel bolt requires evaluating practical, mechanical, and environmental factors together.

Application and load requirement:

- Hex bolts are better suited for heavy-load and structural applications.

- Allen bolts are ideal for machinery, equipment assemblies, and precision components.

Space and design requirements:

- Allen bolts work well in compact or restricted spaces where external tool access is limited.

- Hex bolts are preferred where open access allows easy tightening with standard tools.

Load and torque needs:

- If high tightening torque and easy grip are required, Hex bolts perform reliably.

- For controlled torque and reduced risk of over-tightening, Allen bolts are a better choice.

Environmental conditions: Exposure to moisture, chemicals, or outdoor environments requires selecting the appropriate stainless steel grade to ensure corrosion resistance and long service life.

Shreeji Engineering Works supports customers in choosing the right bolt type, size, and grade, ensuring the fastening solution matches both technical and operational requirements.

Reckoned for the exceptional stainless steel bushings; we are a trustworthy supplier in this domain. we m read more...

Why Choose Shreeji Engineering Works for Stainless Steel Bolts

Shreeji Engineering Works is a trusted name in stainless steel fastener solutions, offering high-quality Allen and Hex bolts manufactured using premium-grade stainless steel. Each product is precision-engineered and finished to meet industry standards, ensuring consistent performance, strength, and durability.

With a wide range of sizes, grades, and specifications available, the company caters to diverse industrial requirements, from machinery and engineering to construction and infrastructure projects. Backed by reliable supply capabilities and customer-focused service, Shreeji Engineering Works stands as a dependable partner for businesses seeking quality, consistency, and long-term value in stainless steel bolts.