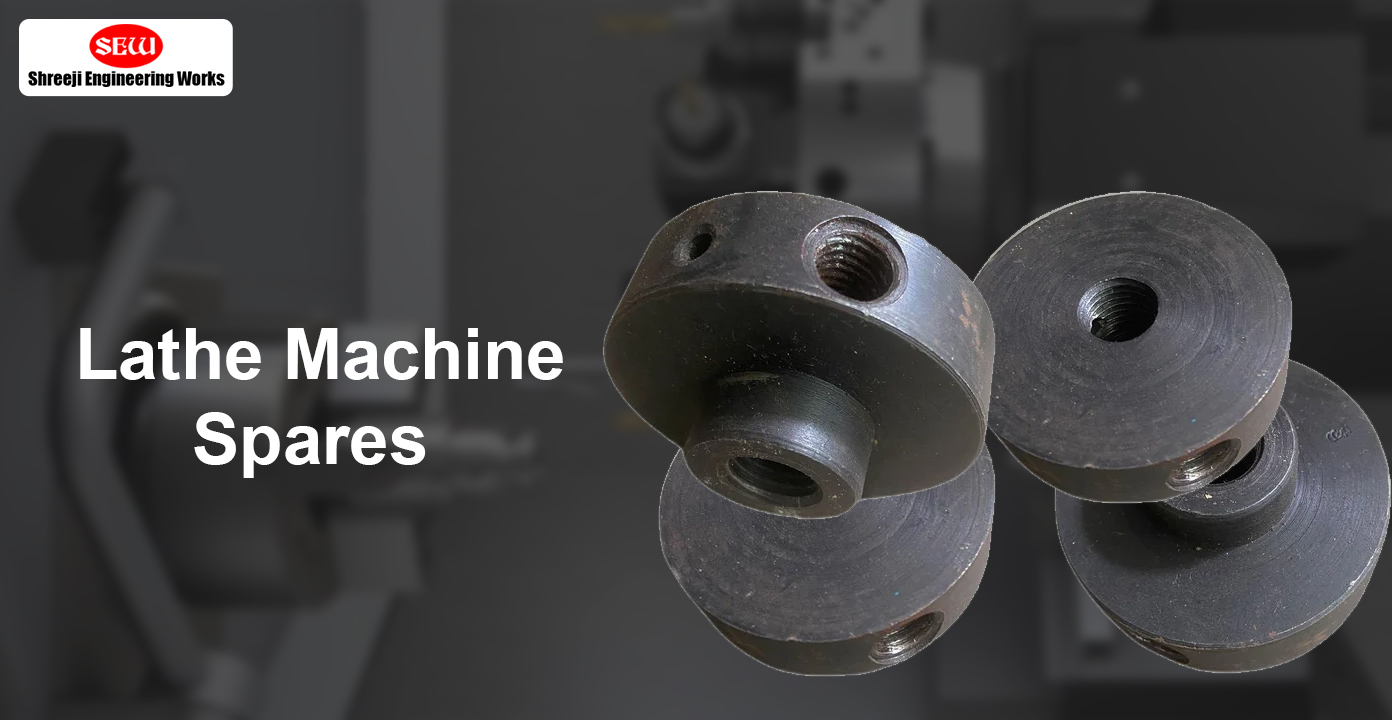

Every efficient workshop relies on more than just powerful machinery — it depends on the quality of the components that keep those machines running. Lathe Machine Spares may seem like small parts, but they are the silent engines of precision and reliability.

From stainless steel NPT bolts to mild steel washers and foundation bolt sets, each spare plays a critical role in ensuring mechanical stability, rotational accuracy, and operational safety. As a leading Manufacturer and Service Provider, Shreeji Engineering Works delivers high-precision lathe spares that uphold industrial efficiency, reduce downtime, and extend equipment life.

Understanding the Role of Lathe Machine Spares in Industrial Operations

Lathe machines operate under constant load, vibration, and torque. Their components, bolts, bushings, and washers must withstand friction, pressure, and temperature changes while maintaining precise alignment.

Without quality spares, even the most advanced machines face performance drops, misalignment, or mechanical failure. This is why workshops that rely on continuous operation depend heavily on accurate machining and durable materials areas where Shreeji Engineering Works excels through its deep technical understanding and strict manufacturing control.

Technical Composition of Key Lathe Machine Spares

As we have marked a distinct name in the market, we are recognized as the trusted organization for supply read more...

We share a forefront with the famed organizations, supplying superior quality stainless steel sew needle read more...

We are identified as one of the commendable names in the market offering cnc machine mould die at afforda read more...

Backed by a hardworking team, we are capable of offering the stainless steel needle valve as per the exac read more...

1. Stainless Steel NPT Bolts

These bolts are engineered for secure mechanical fastening in threaded connections that require tight sealing under pressure. Made from AISI 304 or 316 stainless steel, NPT (National Pipe Thread) bolts offer:

- High corrosion resistance,

- Dimensional accuracy for thread engagement,

- Smooth torque performance without seizing,

- Extended life in high-vibration environments.

Used in fluid lines, mechanical assemblies, and base fixtures, they form the core of precision fastening in lathe assemblies.

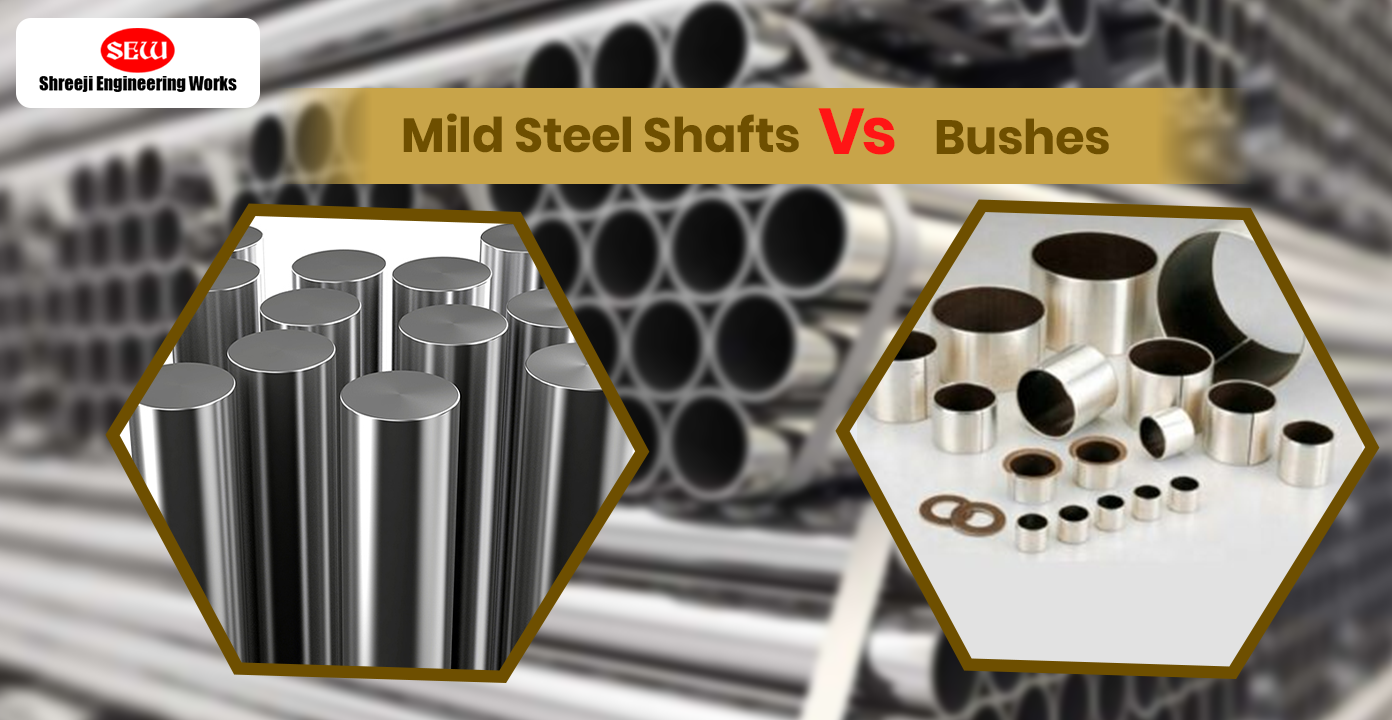

2. Stainless Steel Bushings

Bushings are mechanical linings that absorb friction between moving components. Shreeji’s stainless steel bushings are CNC-machined to micron-level tolerances for smooth motion. Their key features include:

- Resistance to deformation under high load,

- Uniform internal diameter for stable shaft rotation,

- Superior wear resistance due to fine-grain structure,

- Compatibility with lubricants and cooling fluids.

They enhance shaft stability and minimize vibrations during tool rotation.

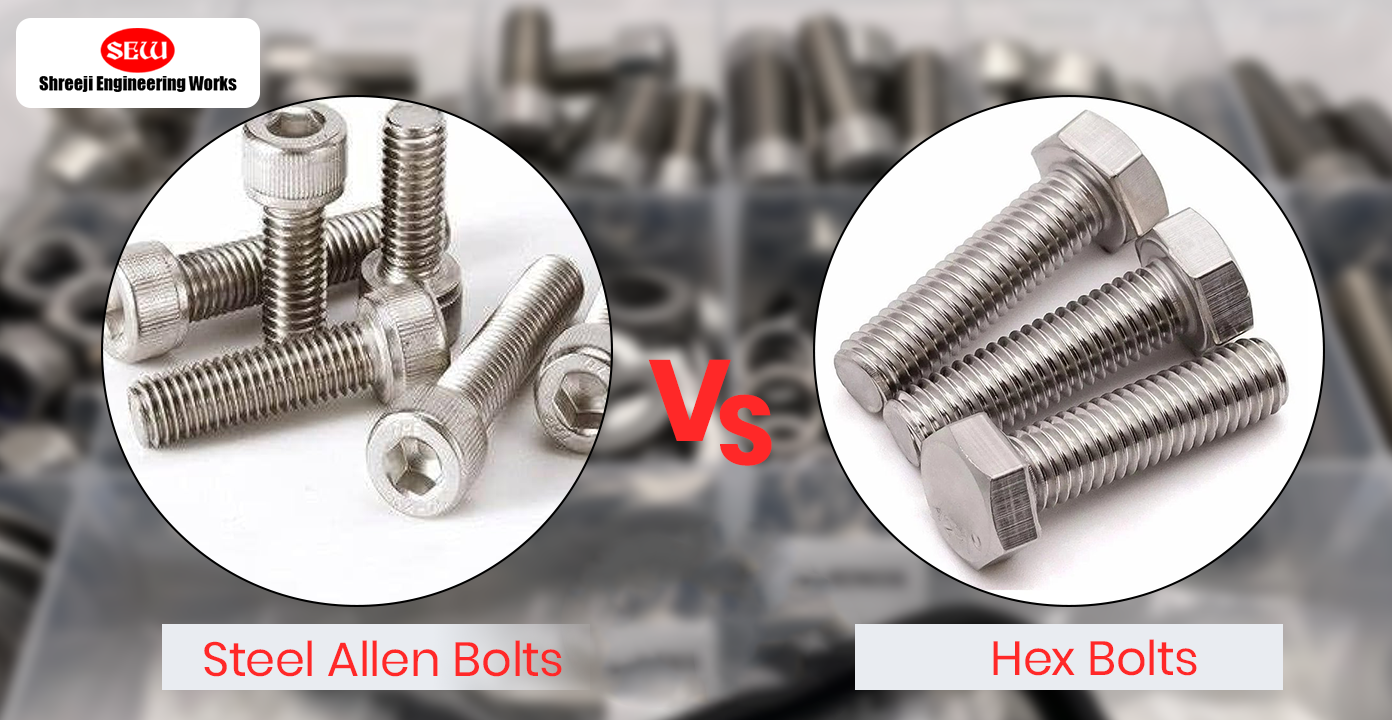

3. Stainless Steel Allen Bolts

These high-torque bolts feature internal hexagonal drive heads, offering easy installation with minimal surface protrusion. Manufactured using precision threading machines, they ensure tight, vibration-proof fastening.

Their main technical benefits:

- Tensile strength above 800 MPa,

- Rust-proof finish for moisture-prone environments,

- Easy maintenance with standard hex tools.

Allen bolts are often used for chuck mounting, tool holders, and motor couplings.

4. Mild Steel Washers

Washers distribute clamping force uniformly and prevent surface damage under bolt heads or nuts. Shreeji Engineering Works produces Mild Steel (MS) washers with controlled hardness and flatness tolerance within 0.1 mm.

Advantages include:

- Reduced stress concentration,

- Rust-protected coating,

- Custom outer and inner diameters for diverse lathe assemblies.

These are essential in ensuring long-lasting, vibration-resistant mechanical joints.

5. Mild Steel Foundation Bolt Set

The foundation bolt set anchors the lathe machine securely to its base. Manufactured from graded mild steel (EN8, EN19), each bolt is heat-treated for strength and elasticity.

Technical characteristics:

- Yield strength above 550 N/mm²,

- Precisely threaded ends for alignment,

- Zinc-coated for corrosion protection.

They eliminate machine displacement during high-speed operations, maintaining performance stability.

Material Science Behind the Durability

Each lathe machine spare is crafted with material chemistry in mind.

- Stainless Steel (304/316): Used for bolts and bushings, offering resistance against oxidation, moisture, and solvents.

- Mild Steel (EN Series): Chosen for washers and foundation sets where strength and weldability are vital.

- Heat Treatment and Surface Finishing: Enhance hardness, wear life, and resistance to mechanical fatigue.

The company’s strict metallurgical testing ensures every spare retains its microstructural integrity even after long operational cycles.

Technical Specifications of Lathe Machine Spares

| Parameter | Typical Specification |

|---|---|

| Product Name | Lathe Machine Spare |

| Material Composition | Stainless Steel and Mild Steel |

| Components Covered | NPT Bolt, Allen Bolt, Bushings, Washers, Foundation Bolt Set |

| Grade | SS 304, SS 316, EN8, EN19 |

| Tensile Strength | Up to 850 MPa |

| Surface Finish | Polished or Zinc-Coated |

| Thread Type | Metric and NPT Thread Standards |

| Hardness | 35–45 HRC |

| Corrosion Resistance | High in acidic and humid conditions |

| Dimensional Accuracy | ±0.02 mm |

| Operating Temperature | Up to 300°C |

| Application | Lathe, Milling, and CNC Machine Assemblies |

| Tolerance Range | ISO 2768-mK compliant |

| Manufacturing Technique | CNC Turning and Thread Rolling |

| Heat Treatment | Normalized and Tempered |

| Testing Standard | IS 1367 and ASTM A193 |

| Lifespan | Over 3 years under continuous operation |

| Packaging | Rust-proof and oil-sealed |

| Manufacturer | Shreeji Engineering Works |

| Country of Origin | India |

Performance Impact: Why Quality Spares Matter

The performance of a lathe depends on how well its mechanical components interact. Low-quality spares introduce micro-gaps, misalignment, and vibration, causing early tool wear and poor surface finish.

In contrast, high-grade spares from Shreeji Engineering Works ensure:

- Smooth rotational accuracy,

- Reduced tool chatter and vibration,

- Extended spindle and bearing life,

- Stable torque transmission under heavy machining loads.

In large-scale workshops and tool rooms, these benefits translate directly to productivity gains and reduced maintenance downtime.

Quality Assurance and Testing Protocols

Shreeji Engineering Works follows a multi-stage inspection and quality protocol aligned with ISO 9001 and IS 2062 standards. Each batch undergoes:

- Dimensional tolerance testing,

- Thread pitch accuracy inspection,

- Surface coating adhesion test,

- Hardness and tensile strength evaluation,

- Salt spray test for corrosion resistance.

Every parameter is recorded and traceable, ensuring reliability and repeat performance across global client orders.

Service Integration and Customization

Beyond manufacturing, Shreeji Engineering Works also acts as a Service Provider, offering maintenance, installation, and retrofit solutions for old lathe setups. They provide customized fasteners and spares tailored to specific spindle sizes, torque loads, or environmental conditions.

This integration of design, supply, and after-sales support positions the company as a one-stop partner for industrial machine maintenance.

About Shreeji Engineering Works: Precision through Expertise-

Shreeji Engineering Works, a reputed Manufacturer and Service Provider of Lathe Machine Spares, has built its legacy on engineering discipline and quality craftsmanship. With decades of experience, the company delivers components that combine precision machining, material strength, and superior finish.

Their product range including Stainless Steel NPT Bolts, Allen Bolts, Bushings, Washers, and Foundation Bolt Sets — serves industries from metal fabrication to heavy machinery. Every spare reflects the company’s commitment to reliability and long-term client trust.

FAQs:

1. What are the most commonly used lathe spares?

Stainless steel bolts, bushings, mild steel washers, and foundation bolt sets are among the most vital components.

2. How are Shreeji Engineering Works spares different?

They are precision-machined, material-tested, and certified for durability and dimensional accuracy.

3. Can these spares be customized for different machine types?

Yes, the company offers custom design and machining services for varied industrial lathe configurations.

4. What materials are used for manufacturing these spares?

A combination of stainless steel (304, 316) and mild steel (EN8, EN19) ensures balanced strength and corrosion resistance.

5. How can I ensure long life of lathe machine spares?

Regular lubrication, proper torque settings, and using genuine spares from Shreeji Engineering Works enhance lifespan and reliability.